BREW HOUSE TECHNOLOGY

Brew House Safety

Learn how to respect and stay safe (and legally compliant) in an environment of hot liquids under high pressure. In a brewery or distillery potential danger is everywhere. To avoid accidents learn the levels of safety and what proactive steps need to be addressed to protect staff and others.

BREW HOUSE TECHNOLOGY

Brewing Engineering

Tour an operating brewery and apply what you know to how the brewhouse system is set up by layout function and equipment. Learn how large scale production works from the mill room through packaging of final product. How fluids are controlled and how to set up a glycol system..

BREW HOUSE TECHNOLOGY

Draft Systems

Learn the proper equipment and standards from our expert instructor in this too-often overlooked system of product delivery. The fundamentals of draft systems make you more money and make your customers happier. Topics such as FOB controls and which type draft system is the optimum for your taproom as well as, how to clean and maintain lines.

BREW HOUSE TECHNOLOGY

Engineering and Fluid Dynamics

Brewing and distilling equipment utilizes fluid dynamics, fluid and gases under heat and pressure, pipes, pumps, motion and physics. You will learn the fundamentals and details to understand what is happening inside the vessels, pipes, pumps, clamps, and hoses.

BREW HOUSE TECHNOLOGY

OSHA-Approved Forklift Training

The ability to safely and legally operate a fork lift and other moving equipment is standard procedure and requirement in this industry. This class gets you competent, compliant and more easily hirable by learning this valuable skill operating a fork lift under certified instruction and guidance.

BREW HOUSE TECHNOLOGY

Sanitation and Quality Control

A brewer and distiller spend most of their time cleaning: FACT! What is a sanitizer? What sanitizers are best? How do you use the sanitizer? What does “CIP” mean? You will explore this vital quality control measure and many others.

BREWING PROCESS

Brewing & Distilling 101

This is an introductory overview to the process, layout and function of a brewhouse. What each kettle is called and how it is utilized in the brewing process.

BREWING PROCESS

Brewing Chemistry I

The more chemistry you know, the better brewer and distiller you will be…” FACT!”. Whether you have majored in chemistry or microbiology or are a beginner and have a hard time spelling the word, we will get you started on the correct pathway to understanding the fundamental chemistry behind brewing and distilling. From the atomic and molecular level to the pathways of yeast metabolism to how esters, acetates, phenols and diacetyl are formed.

BREWING PROCESS

Cellaring | Yeast & Fermentation

Cellaring begins “after the heat exchanger.” Discover the equipment, oxygenation techniques and function, yeast pitching strategies, whirlpooling, filtration, carbonation and taking care of the fermentation process. Many entry-level positions begin with this valuable and essential information and skills.

BREWING PROCESS

Flavor Production/Off Flavors

Desirable beer and spirit flavors arise from a variety of chemical sources that occur throughout the brewing process, as do unwanted off-flavors. These chemical compounds can define a beer style or create an undrinkable beverage. You will be learn through sensory practice to identify – smell, taste, even see and feel – what is supposed to be there and what is not—and,… how to repeat it or correct it. This course is vital to quality and consistent product.

BREWING PROCESS

Packaging

When your product is ready for your consumer, what will be the method of delivery, cans or bottles. If bottles, what types of glass? If cans, what size(s) and packaging configuration? In a competitive marketplace and on a crowded retail shelf what are my choices that will promote my brand, product, and appeal to the consumer? What type of packaging will I need to consider for each marketplace touchpoint from a primary to secondary or tertiary packaging consideration?

BREWING PROCESS

Wort Production & Mashing

Wort: the final goal of brewing; the “sugar water” that takes the correct raw materials, water profile, equipment, temperature and pH so yeast can perform their magic. Discover the enzymes that are ‘in charge’ of this labor-intensive process and how to best ensure they perform to their utmost potential.

BREWING PROCESS

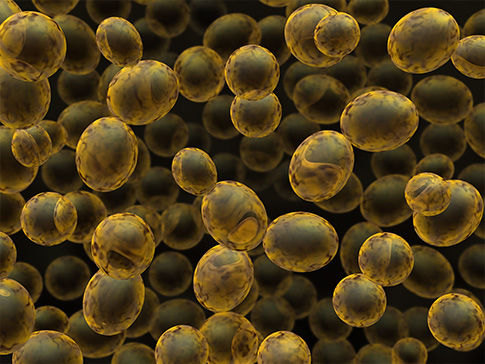

Yeast: Fermentation

“Brewers are yeast farmers and care givers.” Learn that the function of the yeast is not to just produce ethanol and carbon dioxide, but also is essential in determining the style and flavor attributes of beer. In other words, yeast selection is vital to your beer. Learn how and which of the hundreds of yeast varieties to use based on their properties and effect on the final product. How do I keep the yeast healthy and happy so they produce the best quality and most consistent product possible? Learn how to store and re-pitch yeast and how many times you can do that before the yeast is no longer viable?

BUSINESS SKILLS

Brewing Business 1 | Principles

Are you planning to one day open your own brewery or distillery? What instruments do you need in order to attain financing for equipment, property, etc.? What are the necessary elements you need to research and include when building out your business plan? We will go over all the basics you need to start building out your own business plan and pro forma.

BUSINESS SKILLS

Brewing Business 2 | Business Plan

OK, now you get to present your business plan to the class. Using what you've learned in the Brewing Business class. You get to engage classmates with your vision for your business. You will be expected to write a business plan to turn in and create a slide deck for your in class presentation.

BUSINESS SKILLS

Résumé and Interview

Now we review examples of résumés and go over what to include in your résumé. We will also, cover interview techniques and what to do and not do in an interview. You've done the difficult work now let it help you get started in the career you are certified for.

DISTILLING TECHNOLOGY

Distilling 1 | Distilling Equipment

Distilling Equipment

There are different types of distilling equipment: pot stills, column stills and hybrids. What are the advantages of each? Are we making whiskey or gin, vodka or tequila, rum or cordials?

DISTILLING TECHNOLOGY

Distilling 1 | Distilling Process

When does making beer end and producing spirits begin? What is the Ethanol-Water-Equilibrium Curve and how to use it properly? Learn how to determine and to taste difference between the heads from hearts from tails that occur during distillation. And, of course, it’s all about chemistry.

DISTILLING TECHNOLOGY

Distilling 1 | Regulatory Considerations

Regulatory considerations

mean it is not easy to start a distillery. Discover what it takes from the federal, state, and local governmental agencies to legally distill spirits. Our instructors have “been there and are doing that.”

DISTILLING TECHNOLOGY

Distilling 2 | Proofing

My label says this vodka is “90 proof”. What does that even mean? Learn how to get your product there accurately and stay in the federal government’s good graces.

DISTILLING TECHNOLOGY

Distilling 2 | Standards of Identity

Discover what legally is whiskey (or whisky) or vodka or grain neutral spirits or rum. When can I call it: “gin”? Operating a distillery and marketing your products depend on being able to produce products that meet and conform to the Standards of Identity.

DISTILLING TECHNOLOGY

Distilling 3 | Packaging

From barrel aging to bottling using the most modern methods, you need to know how to get your product to your consumer in the best method and most efficient way possible. We also cover how the strict rules of the “three tier” system of distribution affect how your product gets from the distillery to the retailer to the end customer.

DISTILLING TECHNOLOGY

Distilling 3 | Spirit Aging

How long and how do I age my spirit? You will learn the chemistry, philosophy and techniques to generate the best spirit after proper proofing.

INDUSTRY FUNDAMENTALS

Barrel Aging

What can be done to enhance the flavor after fermentation or conditioning? Start by learning the anatomy of barrel types and the cooperage processes that produce them. What type of barrel wood, what level of charring and what chemical compounds are combining to define my product? What beers are best suited for wood aging? This class explores this exciting trend in brewing and distilling.

INDUSTRY FUNDAMENTALS

Barrel Recipe Design

Just like creating our own recipes after gaining and understanding of the definition water profiles give our final product. We are going to add some knowledge, time, barrel attributes and serendipity to compose our own unique barrel aged recipe.

INDUSTRY FUNDAMENTALS

Beer Styles

What is the difference between a porter and a stout; a West Coast IPA a New England IPA? How alike are black lagers and milk stouts? Let’s research this by smelling, tasting and critiquing…anyone say, “I’ll have another sample, please.”

INDUSTRY FUNDAMENTALS

Cider/Mead/Seltzer Making

One of the fastest-growing segments of the beverage industry is one of the oldest: alcoholic beverage based on apples. How does the cider making process differ from beer brewing? How are they similar? We have some of the most progressive hard cider makers instructing this class. Let’s make some cider!

INDUSTRY FUNDAMENTALS

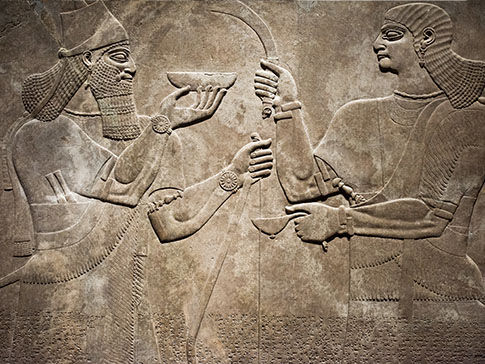

History of Brewing and Distilling

The history of alcohol production and consumption has been an integral and interesting aspect of human history. From a happy Mesopotamian accident to the major form of currency; from wars, to purity laws; from being considered illegal and immoral to becoming an driver for American economic growth and community revitalization, alcoholic beverages have never been dull. Learn from the rich and colorful past of fermentation to enhance your brewing future.

LABORATORY SCIENCE

Brewing Chemistry II

LABORATORY SCIENCE

Microbiology

Brewhouse contaminants are everywhere and just waiting to ruin your beer and your day. Learn what these microbes are all about and how to detect and prevent them. Or,… you just might want to utilize some of these “little guys” to make unique beers!

LABORATORY SCIENCE

Microscope Basics

How do I turn this thing on? Which lens should I be using? What is aperture and how do I control the stage? We will cover all of this as we learn to properly use a microscope so you never have to say, “I can't see anything!”.

LABORATORY SCIENCE

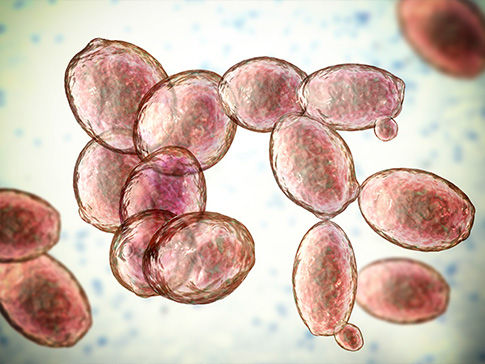

Yeast: Cellular Biology

What is the difference (and similarities) between the Saccharomyces yeasts? Learn what a cell is; different cell types (yeast cell versus a bacterial cell, for example); how cells reproduce; and what type of metabolic pathways they utilize. Apparently, the more biology you know (in addition to chemistry), the better brewer and distiller you will be.

LABORATORY SCIENCE

Yeast: DNA and Mutations

Yeast cells can change or mutate if they get stressed. Learn how this happens and how to prevent it. Discover the difference and similarities between DNA, chromosomes, genes, asexual reproduction and sexual reproduction. It is as fun as it sounds! Discover the first step in mutation generation (a mistake in base pairing during DNA replication). Whaaaat?!

LABORATORY SCIENCE

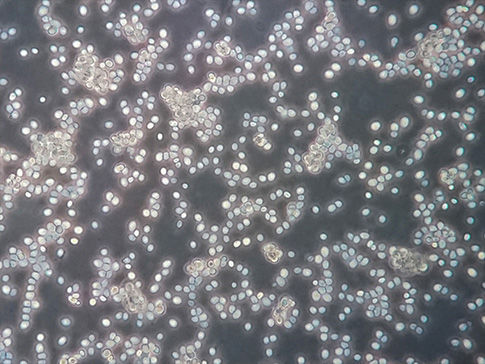

Yeast: Microscope and Cell Counting

We will teach you to not be intimidated by your microscope. Our expert instructors help you become very proficient very quickly utilizing one of the most under-utilized quality control pieces of equipment—the microscope. In a short period of time you will be able to determine how healthy and numerous your yeast cells are to produce the most efficient and consistent of product.

LABORATORY SCIENCE

Yeast: Propagation

This course digs deeper into managing vitality and management of yeast resources in beer and spirits production. Utilizing the Yeast and Fermentation course as a solid foundation, Yeast Propagation details the process of storing, growing, using and reusing yeast in a brew house and still house setting. This immersive hands-on class, intended for the professional brewer and distilling student, covers the why, how, equipment, and issues associated with this important scientific practice.

PRACTICAL TRAINING

Brew House Day 1

Now, let's get up from our chairs and head to the brewhouse to apply and practice what we have been studying to basic beer style recipes in a quality-controlled environment overseen by expert brewers. Time to grind some grain, create mash, troubleshoot issues, boil some wort, add some hops at the correct time and process intervals and choose and pitch some yeast. Then we get to practice our cellaring by filtering and kegging the final product. You will participate in all aspects of beer production: record-keeping, kegging, carbonating and sanitization measures as you have fun doing what you love. There is nothing like working in the brew house and making beer and spirits.

PRACTICAL TRAINING

Brew House Day 2

Now, let's get up from our chairs and head to the brewhouse to apply and practice what we have been studying to basic beer style recipes in a quality-controlled environment overseen by expert brewers. Time to grind some grain, create mash, troubleshoot issues, boil some wort, add some hops at the correct time and process intervals and choose and pitch some yeast. Then we get to practice our cellaring by filtering and kegging the final product. You will participate in all aspects of beer production: record-keeping, kegging, carbonating and sanitization measures as you have fun doing what you love. There is nothing like working in the brew house and making beer and spirits.

PRACTICAL TRAINING

Brew House Day 3

Now, let's get up from our chairs and head to the brewhouse to apply and practice what we have been studying to basic beer style recipes in a quality-controlled environment overseen by expert brewers. Time to grind some grain, create mash, troubleshoot issues, boil some wort, add some hops at the correct time and process intervals and choose and pitch some yeast. Then we get to practice our cellaring by filtering and kegging the final product. You will participate in all aspects of beer production: record-keeping, kegging, carbonating and sanitization measures as you have fun doing what you love. There is nothing like working in the brew house and making beer and spirits.

PRACTICAL TRAINING

Recipe Design

This is our first opportunity to take what we've learned to this point about the raw materials and process of brewing and implement it in a recipe design.

RAW MATERIALS

Raw Material: Hops

Discover the most unique of alcohol production ingredients and how it adds so many different characteristics to beer. Learn how and where it is grown; it’s growing importance to American farmers; the many different varieties and what beer styles this wonderous plant either is a subtle participant or is the star of the show. Ahh, hops.